Steel Pole Restoration

Galvanised steel poles are one of the most common poles that are used to connect aerial service mains in residential areas. The reason? Cost. A galvanised steel pole can cost just a few hundred dollars compared with timber and composite fibre poles which can be over $1,000. Installation. Most ASP’s can carry steel poles on the back of their ute and a stand them without the need for cranes or other machinery. Aesthetics. Galvanised steel poles are more visually pleasing than larger timber and composite poles. This is why many consumers select galvanised steel poles.

R&R - Rust and Restoration

Unfortunately, galvanised steel poles have a shorter life cycle than timber and composite poles. Interestingly, one network operator stated that the composite poles have a life expectancy of at least 70 years!

Whether it is the acidity or salinity of the soil, the overly zealous wiper snipper operator or a poor installation; galvanised steel poles are susceptible to corrosion. Hence, all galvanised poles require some R&R, rust removal and restoration.

The Process

Generally the restoration process has three stages. 1. Assess; 2. Clean; 3. Protect.

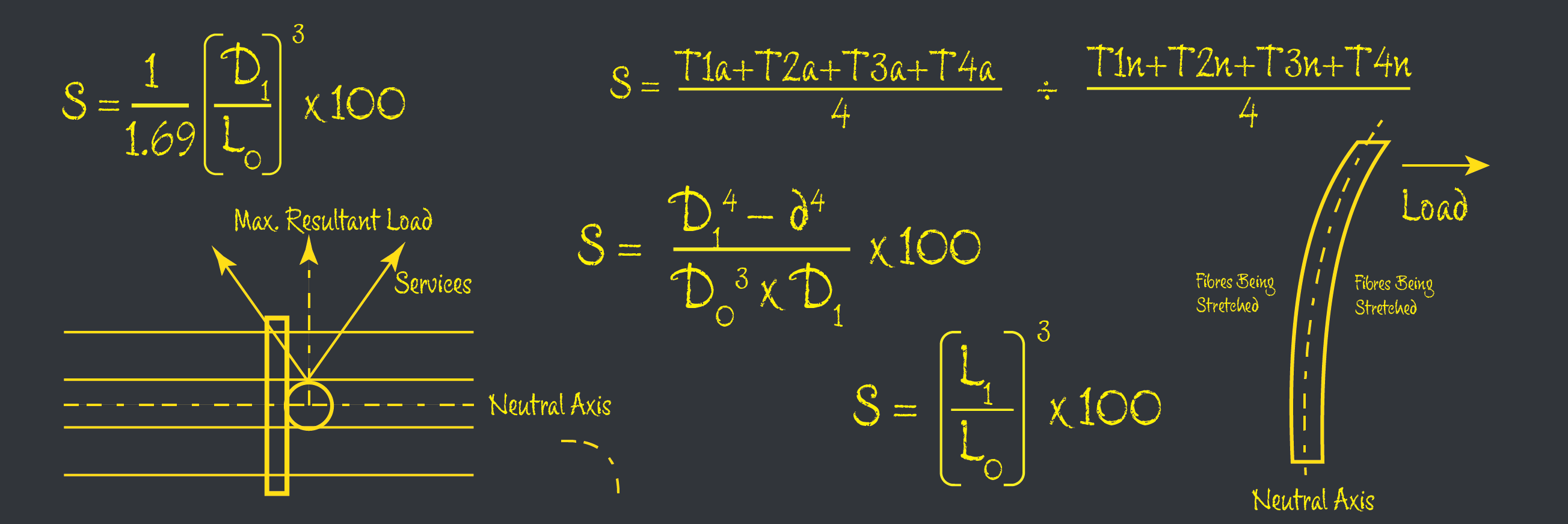

- Assess – a qualified pole inspector will need to assess the asset. He can use ultrasonic testing to verify integrity of the asset and whether the pole has enough residual strength to warrant restoration. He also takes into account the age of the asset and other factors the consumer should know prior to investing in the R&R process.

- Clean – if the pole is deemed suitable for restoration, the inspector will perform a cleaning process to remove all corrosion and debris to ensure the surface is ready for the next stage. Note: this should only be done by qualified electrical experts who undertake a risk assessment and have the relevant SWMS’ in place to control any electrical hazards.

- Protect – with the asset fully cleaned the technician can apply the chemical component to seal and protect the asset from deterioration and corrosion. For example, industrial grade polyurethane coatings have proven to be excellent protectants for such applications.

Call The Experts

Our team have decades of experience and training in pole treatments. What’s more we only use qualified inspectors (UET20619). Why not drop us a line or email and enquire about our R&R services.

Maintenance today prevents replacement tomorrow.